Updating on the dimensional criteria for the design of ‘Ex d’, ‘Ex de’ enclosures for Panel Boards: the new standard of cable entry

08/21/2018

The updated Standard is the IEC 60079-14/EN 60079-14/IEC 60079-14 and, especially, has been changed the concept of cable entry, as described below:

- IEC 60079-14:2007-12, paragraph 10.4.2 selection of cable glands

- EN 60079-14:2008-10, paragraph 10.4.2 selection of cable glands

- CEI EN 60079-14:2010-02, para. 10.4.2 selection of cable glands (hereinafter named only as 60079- ...., as virtually identical).

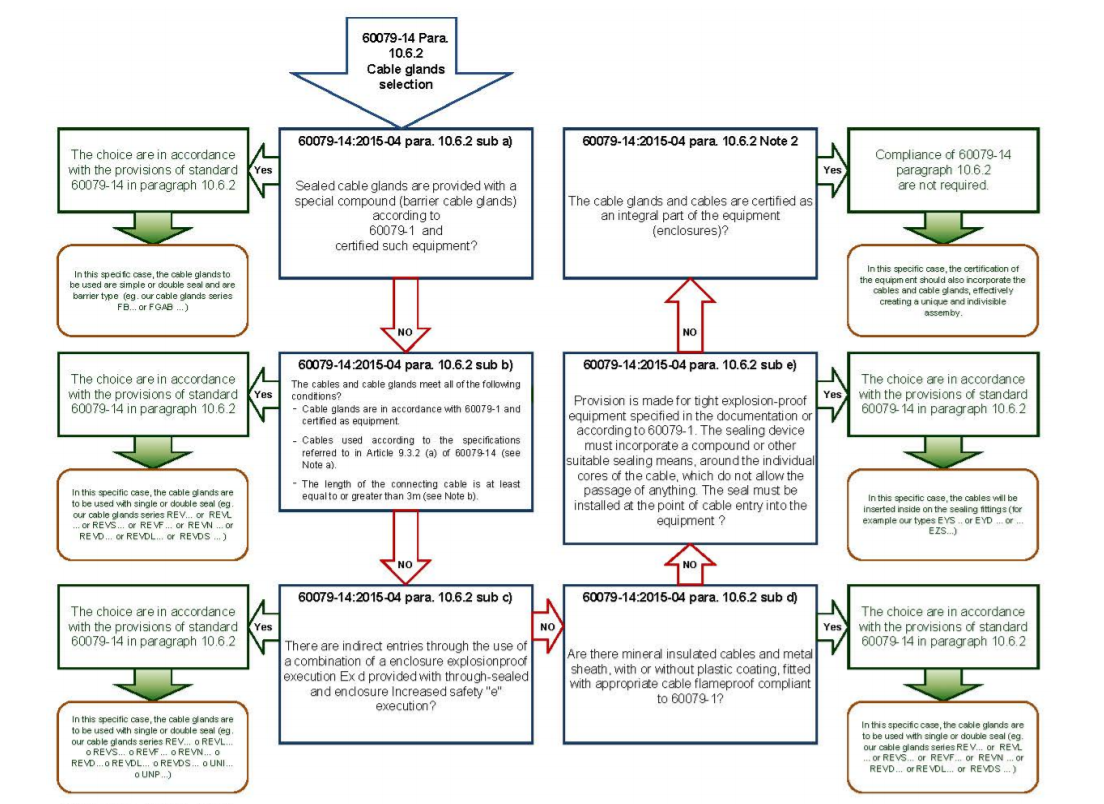

Before this change, the design had to be carried out considering the following basic criteria: - If the enclosure contains a source of ignition and if the dangerous gas requires an IIC enclosure, shall be predisposed sealing fittings or barrier cable glands or - if the enclosure contains a source of ignition and if the dangerous gas does not require a IIC junction box and if the installation area is zone 1 and if the volume of the housing is greater than 2 dm3 , must be predisposed sealing fittings or barrier cable glands or - if the enclosure does not contain a source of ignition, must be used cable glands with simple or double seal provided with full compliance certification or - if the enclosure contains a source of ignition and if the dangerous gas does not require a IIC junction box and if the installation area is not zone 1, must be used cable glands with single or double seal provided with full compliance certification or - if the enclosure contains a source of ignition and if the dangerous gas does not require a IIC junction box and if the installation area is zone 1 and if the volume of the enclosure is not more than 2 dm3 , must be used cable glands with single or double seal provided with full compliance certification The new standard 60079-14, at paragraph 10.6.2 describes the new criteria to be adopted for cable entry/exit from junction boxes, parameters which are summarized in the new flow chart below.

This modification has involved a radical change of concept: the volume limitation for the installation of not barrier cable glands or sealing fittings, the need to verify, with tests, the cable seal or the systematic adoption of barrier cable glands or sealing fittings, the first placed directly into the threaded hubs of the junction box and, the second, in the extreme vicinity of the enclosure, respecting the provisions of the paragraph 13.5.3 of the 60079-1 Standard.

- At point a) of para. 10.6.2 is requested that the cable glands must be sealed (barrier cable glands), comply with the standard 60079-1 and be certified as equipment or -

- at point b) of para. 10.6.2 is requested that the cable glands must be sealed (barrier cable glands), comply with the standard 60079-1 and be certified as equipment and that the cables used must have a sheath in thermoplastic material, thermosetting or elastomeric, of circular compact form and any padding or sheathing must be extruded and any fillers must be of nonhygroscopic material (see paragraph 9.3.2 Standard 60079-14); and

- that the length of the connected cable should be at least 3m, minimum cable length to limit the potential danger of the flame transmission through the cable (see Annex E Standard 60079-14) or - at point c) of paragraph 10.6.2 is requested the indirect entry using a combination of a flameproof enclosure with flame path and a increased safety enclosure with a terminals. Between the two enclosures must be provided one or more sealed bushings or

- at point d) of paragraph 10.6.2 is requested a mineral insulation cable and with metal sheath, with or without plastic covering and that the cable is provided with suitable explosion-proof cable glands compliant with 60079-1 standard or

- at point e) of paragraph 10.6.2 is requested a explosion-proof sealing device (for example a sealed chamber) specified in the equipment documentation, or comply with the standard 60079-1, provided with an appropriate cable gland. This sealing device must incorporate a compound or other appropriate sealing means, around the individual cable cores, which do not allow the passage of anything. This device must be installed at the entry point of the cable in the equipment.

In order to make a correct sizing of enclosures for the uses described above, it is essential that all parameters are systematically taken into account and used as a method of calculation for determining the size of such cases. Considering that these junction boxes must be suitable for installation in hazardous areas (Ex d, Ex de) and that they are therefore subject to certification by qualified entities recognized at international level, it’s necessary that these sizing conform to all the parameters set by the reference standards, such as:

- IEC 60079-0 / EN 60079-0 / CEI EN 60079-0: Explosive atmospheres – Part 0: Equipment – General requirements;

- IEC 60079-1 / EN 60079-1 / CEI EN 60079-1 Explosive atmospheres – Part 1: Equipment protection by flameproof enclosure “d”;

- IEC 60079-7 / EN 60079-7 / CEI EN 60079-7 Explosive atmospheres – Part 7: Equipment protection by increased safety “e”;

- IEC 60079-14 / EN 60079-14 / CEI EN 60079-14 Explosive atmospheres – Part 17: Electrical installations design, selection and erection. (hereinafter named only as 60079- ...., as virtually identical)

This task belongs mainly to the manufacturer of such equipment, as prescribed by the regulations listed above; however, we intend to provide our customers a wide description of the criteria that we usually take to realize the sizing. These types of enclosures, in succession called "Panel Board", which must be suitable for installation in explosion-proof areas, industrial plant, on drilling/production plant (Off-Shore), on flotation devices used in the drilling and/or production (FPSO), are divided mainly into the following types:

- Power distribution Panel Board

- Lighting distribution Panel Board

- Motor operated valve (MOV) Panel Board

- Motor starting Panel Board

- Local control Panel Board

- Marshalling Panel Board

- Feeder electrical tracing Panel Board. The types of construction for these Panel Boards consist essentially of:

- “Directly” cable entry, type (‘Ex d’ way of protection)

- "Indirect" cable entry, type (‘Ex de’ way of protection).

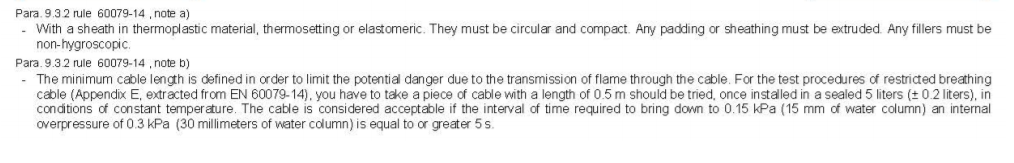

The "Directly" cable entry provides for the entry of cables directly in the "Ex d" Panel board with the use of sealed cable glands, if you adopt the concept described in paragraph 10.6.2 b), or barrier cable glands if you adopt the concept described in paragraph 10.6.2 point a), which not allows to a possible explosion within the Panel board to propagate outside. In this case, the choice of the cable gland or of the sealing fitting shall meet the standard requirements, such as Figure 1.

Figure 1 Execution conform to the pos. e) of paragraph 10.6.2 rule 60079-14 Execution conform to the pos. a) of paragraph 10.6.2 rule 60079-14

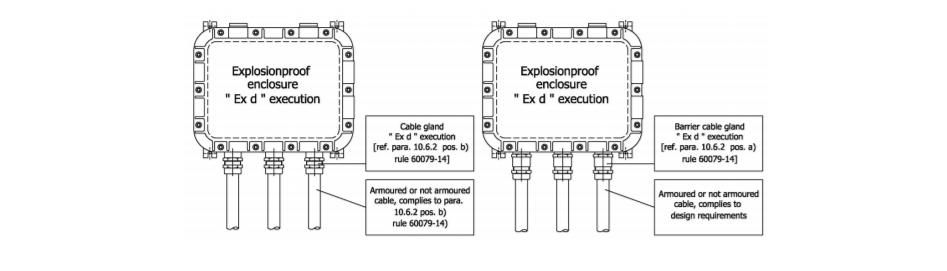

The "indirect" entry involves the use of an increased safety "Ex e" junction box for input/output cables, within which are housed the increased safety terminal blocks. From this enclosure are derived all the links from and to the "Ex d" explosion-proof enclosure. The passage between the two enclosures will be through sealed locking devices and/or sealed bushings, always in ‘Ex d’ way of protection. In this case, the choice of the sealing fittings and/or the sealed bushings has to comply with the requirements of standard, such as Figure 2.

Figure 2

Typical of “Ex de” “indirectly” entry

If the cable glands and the cables used are certified as unique and indivisible part of the equipment (enclosure), it is not required the conformity, according to what is written in paragraph 10.6.2 of the standard 60079-14 (see Note 2 of paragraph 10.6.2 of the same rule). As regards the mechanical and electrical dimensioning, we refer to what is described in the technical article by May 2014.