Understanding the IECEx Non-Electrical Scheme

07/18/2017

When it comes to the compliance of electrical equipment used in hazardous locations, the processes and conformity routes are pretty well known amongst the manufacturing community. Yet the same cannot necessarily be said for mechanical (non-electrical) equipment used in hazardous locations around the globe. Most national and regional conformity schemes cover the explosion protection requirements of electrical equipment only, yet with incidents in hazardous locations occurring through mechanical friction, overheating equipment and mechanical failure, the ignition risks that mechanical equipment may contain cannot be underestimated.

The ATEX Directive 2014/34/EU (covering both electrical and non-electrical equipment used in hazardous locations within the EU) is a leading example of how mechanical equipment is considered and assessed when it comes to explosion protection.

And it was this methodology and best practice that helped lead to the IECEx scheme (the hazardous location scheme under the IEC umbrella) increasing its scope to include non-electrical equipment into their scope.

The IECEx mission

The main goal of IECEx is to create a single international scheme covering certification to standards that relate to equipment, services and personnel operating in potentially explosive atmospheres, providing an internationally accepted means of demonstrating compliance with International Standards. IECEx schemes cover certified equipment, certified repair and certified personnel.

Whilst IECEx is a voluntary certification scheme, the number of IECEx certificates and test reports being issued continues to increase year on year (source: www.iecex.com) as the popularity of the scheme grows.

Historically, the scope of the IECEx certified equipment scheme covered electrical equipment. In 2008, it was decided to create a standard covering non-electrical equipment and components – to include Ignition hazard assessment on the basis of EN 13463-1.

The requirements for this movement were drafted into two standards:

• ISO 80079-36: Basic method and requirements

• ISO 80079-37: Non electrical type of protection constructional safety 'c', control of ignition source 'b', liquid immersion 'k'

In 2016, the standards were issued and today several IECEx Certification Bodies are accredited to issue IECEx Certificates for non-electrical equipment.

ISO 80079-36 Scope

ISO/ 80079-36 supplements and modifies the general requirements of IEC 60079-0:2011. The standard addresses the basic method and requirements for the design, construction, testing and marking of non-electrical equipment (e.g. couplings, pumps, gearboxes, brakes, hydraulic and pneumatic motors and any combination of devices to realise a machine, fan, engine, compressor, assemblies, etc). It considers potential ignition sources (ignition scenarios) related to the equipment under consideration under normal operation, foreseeable malfunction and rare malfunction, and specific measures which are applied to the equipment in order to avoid ignition of a surrounding explosive atmosphere. The assessment methodology is similar to that previously used in the superseded EN 13463-1 ATEX Harmonised Standard, in that an Ignition Hazard Assessment (IHA) is conducted. The IHA identifies all potential ignition sources and determines whether they can become effective ignition sources during the expected lifetime of the mechanical equipment.

ISO 80079-37 Scope

ISO 80079-37 covers non-electrical equipment for types of protection ‘constructional safety’ (“c”), ‘control of ignition sources’ (“b”) and ‘liquid immersion’ (“k”).

‘Constructional safety’ (“c”); Avoidance of ignition sources from mechanical failure through good engineering practice (through design & construction).

‘Control of ignition sources’ (“b”); control ignition sources by monitoring safety critical (control) parameters by means of a suitable Ignition Prevention System

‘Liquid immersion’ (“k”); Avoidance of ignition sources by liquid (either by coating or total immersion)

Considerations assessed include Ingress Protection, seals of moving parts, design clearances to avoid internal impacts and adverse frictional contact, design requirements for bearings, couplings, belts, springs, clutches and brakes, vibrations, maximum and minimum operating parameters (including safety critical operating parameters), suitability and effectiveness of lubricants (protective liquids). All these aspects (and more) are considered within the IHA and design modifications made as needed to ensure avoidance of identified ignition sources.

Marking of Non-Electrical equipment under the IECEx scheme

Whilst 80079-37 covers different methods of protection, when it comes to marking of equipment, equipment is marked with the Ex-marking code “h”. There are no additional markings with regard to the specific type(s) of protection applied, in a drive to provide simplicity when it comes to understanding a product nameplate.

How your product can gain IECEx certification

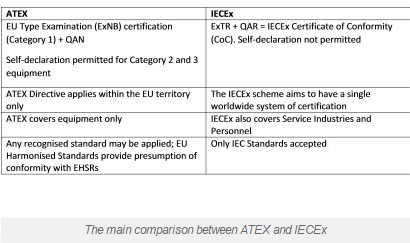

Many non-electrical equipment manufacturers may be familiar with ATEX and have complied with this Directive already, either by engaging with a 3rd party Notified Body, or self-declaring the equipment in compliance with Directive 2014/3/4/EU (depending on the hazardous area zone of use).

As such, an IECEx Certification Body can take some of this assessment as the basis for IECEx approvals. The cost of ‘converting’ an ATEX file to an IECEx certificate, therefore, is relatively low, and IECEx Certification Bodies such as Sira Certification Service (part of CSA Group) can assist you in plotting out the route to conformity.

Perhaps one of the biggest differences between ATEX and IECEx, however, is the need for a quality assurance procedure. Non-electrical equipment that has been self-declared under ATEX does not need an associated Quality Assurance Notification, whereas under the IECEx scheme, a Quality Audit (IECEx QAR) is required. Again, IECEx CBs like can advise on what’s required to gain this.

Importantly however, the international community, spearheaded by IECEx, is making moves to bring the risks, and standardised safety solutions relating to non-electrical equipment, higher up the agenda of consideration when it comes to explosion protection. And, as it’s a relatively low-cost exercise for manufacturers to gain IECEx approvals, it’s anticipated that the demand and drive in industry for IECEx certified non-electrical equipment will increase in the same way as the other existing IECEx schemes continue to do.

Original link from: http://www.hazardexonthenet.net/article/134159/Understanding-the-IECEx-Non-Electrical-Scheme.aspx