PNEUMATICS AND POTENTIALLY EXPLOSIVE ATMOSPHERES: EUROPEAN DIRECTIVE 2014/34/UE (ATEX)

12/05/2017

The main innovations introduced by the new directive 2014/34/UE are:

- Inclusion of non-electrical equipment and devices, such as pneumatic cylinders.

- Each device is assigned a category associated to certain potentially explosive atmospheres.

- All products must bear the CE marking.

- Instructions for use and declarations of conformity must be supplied for each product sold for use in potentially explosive atmospheres.

- Products intended for use in potentially explosive atmospheres due to the presence of dust come under this directive, as do products destined for areas in which hazardous gases are present.

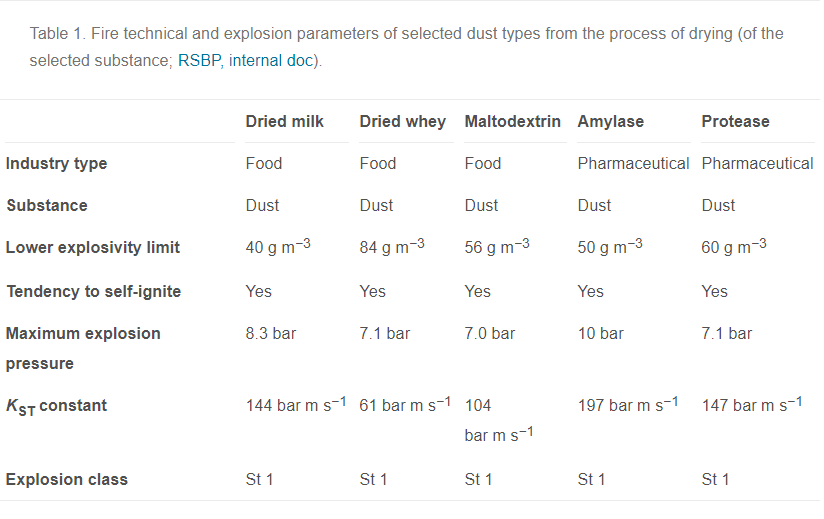

A potentially explosive atmosphere may contain gases, mists, vapours or dust that form in factories or other areas in which flammable substances are continuously or occasionally present.

An explosion can occur when flammable substances and a source of ignition are present simultaneously in a potentially explosive atmosphere.

A SOURCE OF IGNITION CAN BE:

- of electrical origin (electric arcs, induced currents, heat generated by the Joule effect)

- of mechanical origin (hot surfaces generated by friction, sparks generated by impact between metal bodies, electrostatic discharge, adiabatic compression)

- of chemical origin (exothermic reactions between materials)

- a naked flame

Products subject to approval are all those which, during normal use or due to a malfunction, present one or more sources of ignition for potentially explosive atmospheres.

Responsibility lies both with the manufacturer of the device and whoever installs it in equipment that is to operate in a hazardous atmosphere.

This requires co-operation between the parties to ensure correspondence between the category of device and the hazardous area in which it is to operate.

The manufacturer of the device must comply with the specifications and classify the product according to directive 2014/34/UE. The manufacturer of the equipment, who knows the area in which the device will be operating, must select a suitable device according to the category, pursuant to directive 99/92/EC.

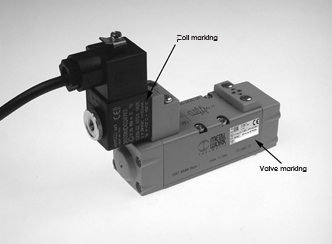

THE COMBINATION OF ELECTRICAL AND MECHANICAL PARTS

According to Directive 2014/34/UE, both electrical and mechanical devices are subject to approval.

It is important to note that the component which is classified in the lowest category defines the category of the entire device of which it is a part. If, for example, the coil is marked Ex II 2 … and the valve is marked

Ex II 3… the coil + valve assembly must not be put into service in zone 1 or 21, only in zone 2 or 22.

GROUPS AND CATEGORIES

Devices for use in potentially explosive areas are divided into the following groups:

• GROUP I: devices used in mines

• GROUP II: devices used in surface installations

DEVICES FOR MINES GROUP I

DEVICES FOR SURFACE INSTALLATIONS GROUP II

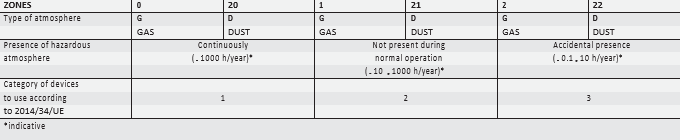

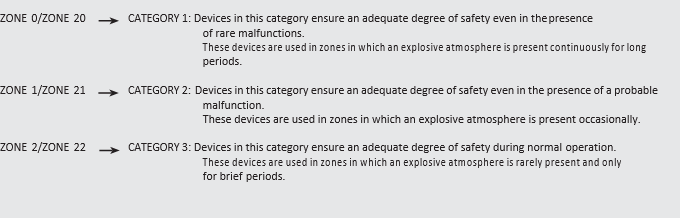

CORRESPONDENCE BETWEEN ZONES AND CATEGORIES ACCORDING TO 2014/34/UE.

MARKING: HOW TO READ IT

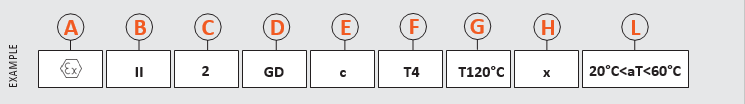

MARKING ON NON-ELECTRICAL EQUIPMENT (UNI EN 13463) MARKING ON ELECTRICAL EQUIPMENT (UNI EN 13463 and CEI EN 60079)

A = Means the equipment can be used in an ATEX zone

B = Group: mining or other industries

C = Category: indicates use in various zones

D = Type of explosive atmosphere: G = gas; D = dust

E = Method of protection from ignition sources: c = protection by constructional safety

F = Temperature class: maximum surface temperature in atmosphere with gas

G = Maximum surface temperature in atmospheres with dust

H = Presence of specific operating conditions

L = Ambient temperature for use of the equipmento

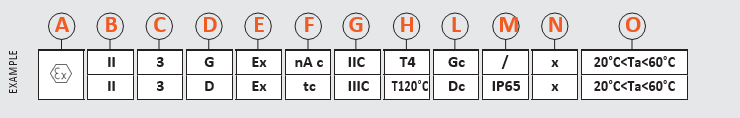

MARKING ON ELECTRICAL EQUIPMENT (UNI EN 13463 and CEI EN 60079) TYPE OF PROTECTION AGAINST SOURCES OF IGNITION

A = Means the equipment can be used in an ATEX zone

B = Group: mining or other industries

C = Category: indicates use in various zones

D = Type of explosive atmosphere: G = gas; D = dust

E = Means the equipment may be used in an ATEX zone

F = Method of protection from ignition sources (more than one possible)

c = protection by constructional safety

tc = protection by enclosures

nA = non-sparking protection

mA,mB = protection by encapsulation

ia,ib,ic = sintrinsic safety

G = Division of the explosivity group

IIC: explosive subgroup that comprises all types of gas

IIIC: explosive subgroup that includes combustible particles, conductive dust and not

H = Temperature class: maximum surface temperature in atmosphere with gas

maximum surface temperature in atmospheres with dust eri

L = Gc = explosive atmospheres due to the presence of gas

Dc = losive atmospheres due to the presence of dust

M = Index of protection

N = Presence of specific operating conditions

O = Ambient temperature for use of the equipmento

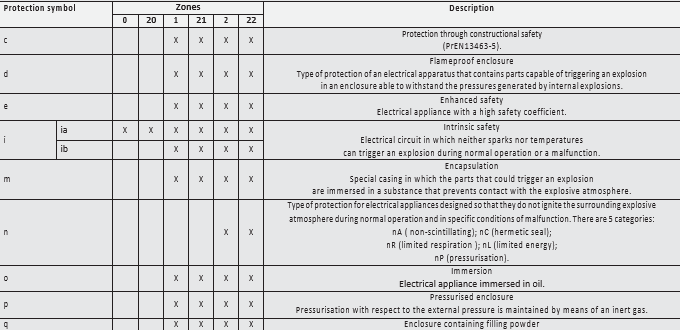

TYPE OF PROTECTION AGAINST SOURCES OF IGNITION

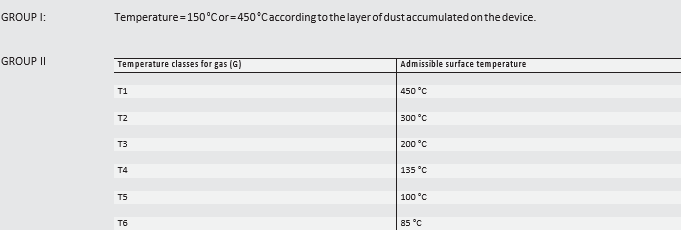

TEMPERATURE CLAS

USER AND SUPPLIER: OBLIGATIONS AND RESPONSIBILITIES

It is important to highlight the need for the user and supplier to collaborate and to exchange all the information required to define the types of products that can be used in full compliance with the safety standards.

USER: after performing a company-wide risk analysis (pursuant to directive 99/92/EC) and identifying the risk zone in which the purchased part will be operating, the user must inform the SUPPLIER, who must check that the products supplied are compatible with the zone indicated and that the environmental conditions are within the set operating range for the parts.

It is also important to make sure that the operating instructions are always attached to the products supplied.

Source: http://www.metalwork.it/img/atex/ATEX_EN_2016.pdf