Identification of your assets in possible hazardous areas

03/14/2017

Many different ways we do have for it: ID card, finger print, eye scanner... in "normal" life... What about industry? What are the most up-to-date solutions for it?

- QR code

- barcode

- sticker

- name plate

- active RFID tag

- passive RFID tag certified as simple device

All are very professional. How they cope with requirements of all above?

QR code, barcode: Visibility / readability is with high importance. It has to withstand any environmental influence. You may need a reader, software for it. It enables automated recognition.

Sticker, name plate: sticker is not for lifetime, even if it is promoted. Visibility / readability is with high importance. It has to withstand any environmental influence. You may need a reader, software for it. It does not enable automated recognition.

Active RFID tag: It has to withstand any environmental influence. You may need a reader, software for it. It enables automated recognition. Lifetime is limited due to internal battery. Ex Certification is a must have. Price is not cheap.

Passive RFID tag certified as simple device: It has to withstand any environmental influence. You may need a reader, software for it. It enables automated recognition.

If we consider all possible solutions (and that is how we did), we have chosen to go our way the passive RFID tag certified as simple device.

Applicable hazardous area classification: 1) Zone 1 IIC T6 / Zone 21 IIIC 85°C an ambient temperature Tamb 40°C; 2) Zone 1 IIC T5 / Zone 21 IIIC 100°C at an ambient temperature Tamb 60°C

Parameters:

- Simple apparatus according to IEC 60079-14

- 13.56 MHz operating frequency

- ISO/IEC 15693-2,-3; ISO/IEC 18000-3 Compliant

- 256-Bit User Memory in 8 x 32-Bit Blocks

- user and Factory Lock Per Block

- Application Family Identifier (AFI)

- Fast Simultaneous Identification (Anti-Collision)

- operating temperature: -25°C to 90°C

- storage temperature: -40°C to 120°C (130°C for total 50hrs, 220°C for total 30s)

- data retention time (at 25°C): >10yrs

- dimensions: Ø 22 ± 0.2 mm x 3 ± 0.2 mm

- weight: 2.1 ± 0.2 gramm

- protection class: IP68

- vibration: ISO/IEC 68.2.6 (10 g, 10 to 2000 Hz, 3 axis, 2.5 h)

- mechanical shock: ISO/IEC 68.2.27 (100 g, 6 ms, 6 axis, 20 times per axis)

- mechanical stability: Axial compression strength: 1000N (10 s, static) Radial compression strength: 500N (10 s, static) Isostatic water pressure: 45 bar (10 h)

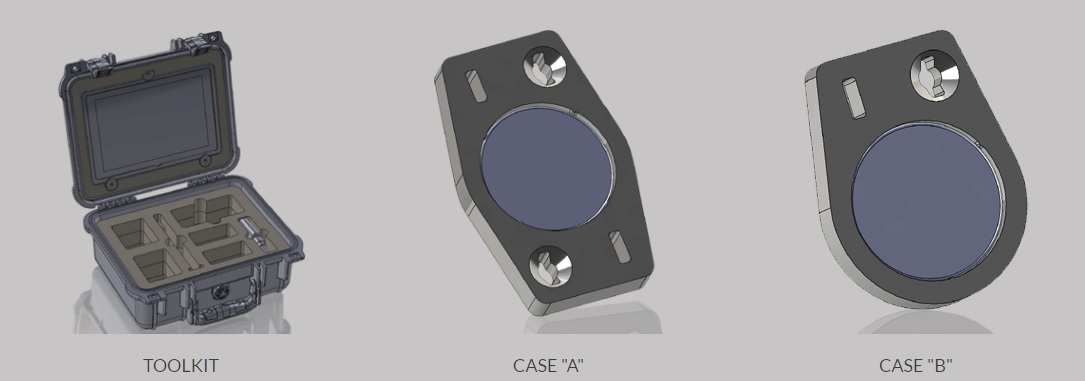

Our ExRFID SA1 makes it happen. It is one single solution for identification and follow up of all your assets in any hazardous area industries. All activities from installation in including maintenance, repair, relocation, etc. can be tracked vis using ExRFID SA1.

There might be one disadvantage. Passive RFID reading distance is just 2-3 centimeters. On the other side it is the advantage is as well. We do expect our inspectors, auditors go to installation and do their job. That way we can have a better performance on all levels: the reader (including installateur, inspector, auditor) is as close as possible.

In case you require a complete system including reader and software, we are there for your assistance.

more information: Ex RFID tag

Mr. Arpad Veress

Ind-Ex Middle East LLC / Veproil Ltd. - veress@ind-ex.ae / veress@veproil.hu - +971 56 568 2854 - +36 30 9660 223