FIBC Types

01/23/2018

|

Plain Bag - No Static Protection Safe use:

Do not use:

|

Type A FIBC are made from plain polypropylene or other non-conductive material. Static electricity is generated as products move over the inside surface of bulk bags when they are filled or emptied. An inherent electrostatic hazard with Type A bulk bags is that they do not have any mechanism for dissipating static electricity and will not prevent the occurrence of highly energetic, and dangerous propagating brush discharges (PBD). As there are no requirements for static control in this type of bulk bag, there are no electrostatic tests specified in standards and no requirements for labelling. Although it is permissible to label bulk bags as Type A FIBC, this is rarely done. Bulk bags that are not labelled as Type B, Type C or Type D, can be assumed to be Type A.

As there is no static protection provided by Type A FIBC, it is essential that they are not used to store or transport combustible materials or used in flammable or combustible environments. Many organic materials such as sugar, flour, corn starch, milk powder, wood pulp, etc. and chemicals such as bisphenol-A, benzoic acid, toner powders, etc. can form combustible dust clouds or layers that can be ignited by electrostatic discharges from Type A FIBC. The safe option for packaging materials of this nature is to use antistatic FIBC that offer full protection against electrostatic hazards, such as CROHMIQ Static Protective Type D FIBC.

Inert, non-combustible materials such as titanium dioxide (TiO2) are often used in processes that involve flammable solvents. There is a high risk of solvent vapours being ignited by electrostatic discharges from Type A FIBC. It is essential that only bulk bags with full static protection are used in any process that involves flammable solvents. In these situations CROHMIQ Static Protective Type D FIBC is the safe option.

|

Plain Bag - Low Breakdown Voltage Prevents Propagating Brush Discharges Safe use:

Do not use:

|

Type B FIBC are similar to Type A FIBC in that they are made from plain polypropylene or other non-conductive material. And like Type A bulk bags, Type B bulk bags do not have any mechanism for dissipating static electricity. The difference is that Type B bulk bags are made from materials that have a low breakdown voltage to prevent the occurrence of highly energetic, and dangerous propagating brush discharges (PBD).

There are two ways to achieve a low breakdown voltage in FIBC made from woven polypropylene. The first way is to use uncoated fabric. Although the polypropylene tapes have a high breakdown voltage, the air gaps in the weave of uncoated fabric has a low enough breakdown voltage to prevent PBD occurring. Clearly, Type B FIBC made from uncoated fabric cannot be used to package powders or other materials that produce fines that might leak through the uncoated fabric. The second way of achieving low breakdown voltage is to apply a very thin coating. However, because of the way coatings are applied to bulk bag fabrics, it is likely that holes and tears will occur in very thin coatings. Although a fabric with a very thin coating may have a low breakdown voltage, it is almost certainly incapable of providing the containment and protection required for packaging powders.

Although Type B FIBC can prevent PBD, they cannot be considered antistatic FIBC because they do not dissipate electrostatic charge and so normal brush discharges can still occur, which can ignite flammable solvent vapours. Antistatic bulk bags must have a consistent and reliable mechanism for dissipating static electricity. It is essential that only proven antistatic bulk bags with full static protection are used in any process that involves flammable solvents. In these situations CROHMIQ Static Protective Type D FIBC is the safe option.

Because Type B FIBC do not dissipate static electricity, there are consequences aside from the risks of incendiary discharges. Brush discharges from Type B FIBC can cause electrostatic shocks to operators. Whilst such shocks are not dangerous in themselves, they can be distracting and may lead to accidents. Another consequence of the build up of static electricity on Type B FIBC is that dust and other contaminants are attracted to the surface. This is clearly not desirable in food and pharmaceutical applications, and other applications where hygiene is critical. Electrostatic attraction can also make it difficult to fully empty Type B bulk bags. Several kilograms of powder can be left clinging to the inside of the bag. When the bulk bag is taken down and moved away from the emptying station, the residual powder may be dislodged and spill out. This again has an impact on hygiene within a factory and is detrimental to good house-keeping practice. Poor house-keeping and the build up of powder and dust has been implicated as a contributing factor in many combustible dust explosions.

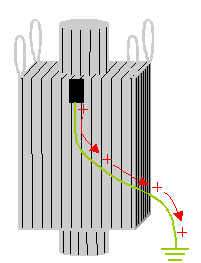

| Interconnected Conductive Threads Dissipates Charge to Ground RG < 107 ohm Safe use:

Do not use:

|

Type C FIBC are also known as conductive FIBC or groundable FIBC. Originally they were made from entirely conductive materials. Today, groundable Type C FIBC are more commonly made from non-conductive polypropylene interwoven with conducting yarns, normally in a grid pattern. The conductive yarns must be electrically interconnected and connected to designated ground or earth bonding points. The ground or earth bonding points must in turn be connected to a system ground or earth during all bulk bag filling and emptying operations.

The interconnection of conductive yarns and the connection to ground or earth are critical to the safe use of Type C FIBC. The interconnection of conductive yarns throughout the bulk bag is achieved by correctly sewing together the panels of fabric that make up the groundable bulk bag. Sewing is a manual operation, as is the connection of the groundable bulk bag to a system ground or earth. As with any manual operation, ensuring interconnection and grounding of Type C FIBC is subject to human error. In his case study review published in "Process Safety Progress", Vol. 12. No. 4. October (1993) , Dr Lawrence G. Britton, in referring to the dangers of ungrounded Type C FIBC, stated "In particular it should be appreciated that the potential for operator grounding error and sudden nemesis can be very high".

Many companies concerned about the very serious dangers of ungrounded Type C FIBC choose to use the safe option of CROHMIQ Static Protective Type D FIBC that provide full electrostatic protection without the need for grounding.

|

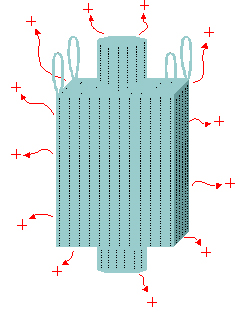

Does Not Require Grounding/Earthing Safe use:

Do Not Use:

|

Type D FIBC are made from static protective fabric designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges, without the need for a connection from the bulk bag to ground or earth.

CROHMIQ Static Protective Type D FIBC are manufactured with fabric containing quasi-conductive yarns that safely dissipate static electricity into the atmosphere via safe, low-energy corona discharge. The quasi-conductive yarns in CROHMIQ bulk bags do not need to be interconnected. CROHMIQ Static Protective Type D FIBC are designed and engineered to provide full protection against electrostatic hazards without the need for grounding. The use of CROHMIQ fabrics in antistatic bulk bags eliminates the risk of human error associated with the manufacturing and use of groundable Type C FIBC.

As CROHMIQ Type D bulk bags protect against incendiary sparks, brush discharges and propagating brush discharges, CROHMIQ can be used safely to package combustible products and for handling products in combustible and flammable environments.

CROHMIQ Static Protective Type D FIBC have been used for over 15 years to safely package over 50 billion pounds of chemicals, minerals, foods, pharmaceuticals, pigments and other products for the world's most demanding applications.

Note: There is no official standard classification, "Groundable Type D", D+, Dplus or CD. IEC 61340-4-4 Ed. 2.0 does not permit FIBC to be labelled as D+, CD, etc. Only the official classifications, i.e. Type A, Type B, Type C or Type D can be indicated on FIBC labels. One FIBC cannot be simultaneously classed as more than one type. So, for example, classing FIBC as both Type C and Type D, or labelling as C/D, etc. is not permitted by IEC 61340-4-4 Ed. 2.0.

Original link from: http://crohmiq.com/fibc-type-a-b-c-d-classification-safety.html