Explosion Protection - Legal bases

04/18/2017

The requirements of electrical equipment for explosive atmospheres are multifarious: national and international regulations, directives and standards must be observed and ensure maximum safety. The following chapter summarises the main legal requirements and recommendations worldwide, in the European Union and in North America to provide the reader with an overview.

EXPLOSION PROTECTION WORLDWIDE

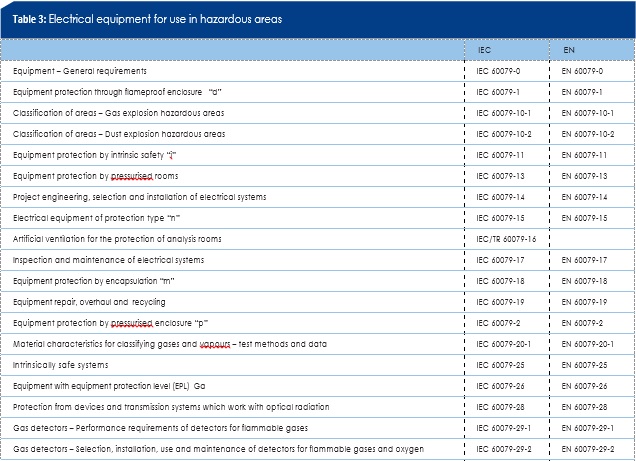

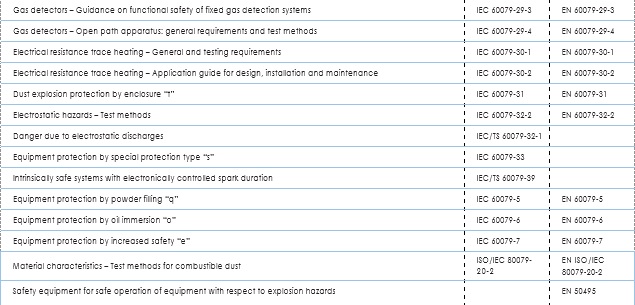

The International Electrotechnical Commission (IEC) is respon- sible for global standards in the field of electrical engineering. IEC publications regarding the explosion protection of electrical equipment and installations are drafted by the Technical Com- mittee TC31 and are deemed as recommendations. All standards observe the latter as far as possible. Until recent years, regula- tions for gas explosion hazardous areas were stipulated in the 60079 standard series and those for dust explosion hazardous areas in the 61241 series. As many requirements are identical for both, the two standard series have now been grouped under IEC 60079. The various methods of ensuring ignition protection for equip- ment are called protection types. They are described in the various sections of IEC 60079 and are construction regulations recognised in many countries (see Table 3).

Systems in hazardous areas must be classified according to their degree of endangerment in respect of the likelihood of the occurrence of explosive atmospheres in zones. IEC drafted two standards for this purpose:

- IEC 60079-10-1: Classification of areas – gas explosion hazardous

- IEC 60079-10-2: Classification of areas – dust explosion hazardous

Further standards are available for the installation and operation of electrical systems:

- IEC 60079-14: Project engineering, selection and installation of electrical

- IEC 60079-17: Inspection and maintenance of electrical

- IEC 60079-19: Equipment repair, overhaul and recycling

In 2016 standards for non-electrical equipment for use in explosive atmosphere were published:

- ISO 80079-36: Non-electrical equipment for explosive atmos- pheres – basic method and

- ISO 80079-37: Non-electrical equipment for explosive atmos- pheres – non-electrical protection type constructional safety “c”, control of ignition sources “b”, liquid immersion “k”.

National regulations may however differ from IEC standards. For this reason the extent to which they may be applied in the respective countries must be verified. As this entails a high out-lay for development and approval procedures particularly on the part of global players, it seemed advisable to subject approval conditions for electrical equipment to international regulations, thus permitting a free global movement of goods on the basis of country or region-neutral certificates. Furthermore, consistent standards should ensure the maximum safety of Ex products throughout their entire life cycle. IEC therefore introduced a procedure with the aim of standardisation: the IECEx Scheme. Recognised IECEx certification bodies (ExCB = certification body) and IECEx test laboratories (ExTLs) exist worldwide and are accredited on the basis of high standard criteria and regularly monitored. An IECEx certificate is only issued if test sample type testing is successful and an audit verifies that an effective quality management system is in place. However, different regional and national approval procedures currently exist all over the world, including for example the ATEX directive in the European Union or national approvals in the USA (UL, FM).

Besides the IECEx Scheme for testing and certifying new prod- ucts (IECEx Equipment Scheme), for some years now the system has also included certification of service providers (IECEx Certified Service Facilities Program). The service provider must prove that it maintains a quality assurance system. It is audited every three years by an accredited auditing body (Ex-CB).

The third component of the IECEx Scheme (IECEx Certification of Personnel Competencies) runs on similar lines. It focuses on the certification of the personal skills of professionals working in hazardous areas. This is designed as a guarantee for global operators that employees possess the necessary qualification and experience to perform with perfection highly complex tasks in hazardous areas.

In the “Recognised Training Provider (RTP)” programme the IECEx organisation examines the competence of providers offer- ing explosion protection courses. A list of training providers is available on the IECEx website.

EXPLOSION PROTECTION IN THE EUROPEAN UNION

Explosion protection is governed by directives and standards in the European Union.

Directives

In 1976 the Council of the European Community established the basis for the free movement of explosion-protected electrical equipment within the European Union with its “Directive on the harmonisation of the laws of the member states concerning electrical equipment for use in potentially explosive atmospheres (76/117/EEC)”. This directive has since been continuously adapted to state-of-the-art standards by means of single and supple- mentary directives, which however only concerned electrical equipment.

Full harmonisation and extension to all types of equipment, both electrical and non-electrical, was achieved in 1994 by the new 94/9/EC (ATEX) directive. This was followed in 1999 by the 1999/92/EC directive, which governs operation in hazardous areas and defines safety measures for the persons working in those areas. In February 2014, Directive 2014/34/EU (ATEX) was published. Actual implementation with regards to equipment certification took place on 20 April 2016, replacing Directive 94/9/EC.

Standards

The European EN 50014 – EN 50020 electrical equipment stand- ards were issued in 1978 and replaced the previous national standards for this equipment valid across Europe. Aside from the electrical equipment standards (published by the European Committee for Electrotechnical Standardization CENELEC), the European Committee for Standardization (CEN) has drafted respective standards for non-electrical explosion-protected equipment.

According to an agreement between the European Committee for Electrotechnical Standardization CENELEC and the Inter- national Committee for Electrotechnical Standardization IEC, international standards for electrical equipment have generally been adopted by CENELEC as they stand. The EN 50014 ff series defining requirements for equipment in explosive gas atmos- pheres has been gradually replaced by the EN 60079 series (at international level IEC 60079). In Germany these standards are issued as VDE 0170.

The requirements of protection types for areas with combustible dust were contained in the IEC 61241 series. In Europe these EN 61241 standards replace the former EN 50281 series. However, since most requirements for gas and dust are similar, they are compiled under the series IEC or EN 60079 (see Table 3)

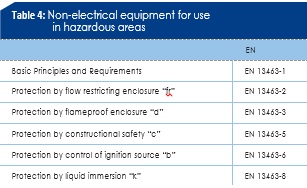

After publication of Directive 94/9/EC in Europe, construction regulations for non-electrical equipment were also specified by the EN 13463 standard series (see Table 4). Some protection principles for electrical equipment were adopted, although amendments were made to address the special requirements of non-electrical equipment. Published in 2016, standards ISO 80079-36 and -37 have been adopted as EN ISO 80079-36 and -37.

Other important harmonised standards on explosion protection worthy of mention are EN 11267-1 and -2. They set out methods by which hazards are identified and assessed and outline the respective protection measures. Both preventive explosion protection (avoiding explosive atmospheres and effective ignition sources) and constructive explosion protection (containing explosion effects) are addressed. With the aim of preventing ignition sources as a protective measure, all ignition sources are described and possible measures for their avoidance defined. While Part 2 is relevant for mines, Part 1 deals with other areas.

- EN 1127-1: Explosive atmospheres –

Explosion protection – Part 1: Basic principles and methods.

- EN 1127-2: Explosive atmospheres –

Explosion protection – Part 2: Basic principles and methods in mines.

INSTALLATION AND OPERATION

Directive 1999/92/EC “Minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres” explains the principles of the operation of systems in hazardous areas. It is thus directed at operators (employers). They must assess the explosion hazard, classify the system into hazardous zones and document all measures to protect employees in the explosion protection document.

Evaluation of explosion risks

When assessing explosion risks, the following should be taken into account:

- Likelihood and duration of the presence of the explosive

- Likelihood of ignition sources being present, activated, and becoming

- Materials and methods used and their possible

- The extent of the expected impacts of explosions

Zone classification

The operator must classify the areas in which explosive atmospheres may be present into zones. It should also ensure compliance with the directive stipulating the minimum require- ments (in an organisational and technical respect).

Explosion protection document

The explosion protection document must compulsorily contain details on the following aspects:

- Risk

- Protection measures

- Zone

- Observance of minimum These are divided into organisational measures (e.g. instruction of employees) and technical measures (explosion protection measures).

Directive 1999/92/EC only contains minimum requirements, which may be freely extended on implementation in national legislation.

SELECTION OF EQUIPMENT

In 1994 EC Directive 94/9/EC “on the approximation of the laws of the Member States concerning equipment and protective systems for use in potentially explosive atmospheres” was issued to further standardise explosion protection in the EU. It was replaced in 2014 by EU Directive 2014/34/EU (ATEX). It stip- ulates the requirements for the quality of explosion-protected equipment and protective systems (e.g. by setting out provisions for conformity assessment, protective levels, certification, manufacture and quality assurance, operating manuals and declarations of conformity), in that it prescribes the essential health and safety requirements which must be satisfied by manufacturers and importers. The directive thus ensures the free movement of goods within the European Union and must be adopted as it stands into national legislation. In Germany for instance, this took the form of the Explosion Protection Product Ordinance as 11th Ordinance of the Equipment and Product Safety Act (11. ProdSV). It applies to all industrial hazardous areas (including mining).

The directive applies to equipment, components and protective systems for use in hazardous areas. It also applies to safety, control and regulating apparatus used outside the hazardous area, if the latter is necessary in respect of explosion hazards for the safe operation of equipment in the hazardous area. The directive does not refer to established standards, but sets out fundamental safety requirements, which are deemed as binding quality requirements. Protection from other hazards (e.g. electric shock) which may be caused by this equipment must also be taken into account.

Equipment means machines, apparatus, fixed or mobile devices, control components and instrumentation thereof and detection or prevention systems which, separately or jointly, are intended for the generation, transfer, storage, measurement, control and conversion of energy and/or the processing of material and which are capable of causing an explosion through their own potential sources of ignition.

Component means any item essential to the safe functioning of equipment and protective systems but with no autonomous function.

Protective systems means devices other than components of equipment that are intended to halt incipient explosions imme- diately and/or to limit the effective range of an explosion. These are generally available in the market for use as autonomous systems.

A hazardous atmosphere means an atmosphere which could become explosive due to local and operational conditions.

Equipment categories

Manufacturers whose equipment may represent a potential ig- nition source and thus may cause an explosion must submit the latter for an ignition hazard assessment. In addition, measures corresponding to the fundamental safety requirements should be envisaged to preclude the risk of ignition by this equipment. The directive classes equipment for hazardous areas (with the exception of mine workings) into three categories with different levels of safety. The required protective measures are adopted to the respective required level of safety.

Conformity assessment and certification

Equipment for use in hazardous areas must first be submitted to the conformity assessment procedure prescribed by the directive before being put into circulation or on the market.

Category 1 and M1 equipment must be submitted to a type approval test and certification by a notified inspection authority.

The same applies to Category 2 and M2 electric equipment and combustion engines. Manufacturers can determine and document conformity with the directive requirements for other non-electric equipment in this category and for Category 3 equipment. The certificates from a notified inspection authority are recognised throughout the EU. Existing EC type examination certificates continue to retain their validity under the new EU Directive 2014/34/EU.

Marking

EU Directive 2014/34/EU requires special marking:

- CE

- Symbol Ex with group, category and additional letter G

Operating instructions

The manufacturer’s operating instructions must clearly define the intended use of the equipment by the operator. Minimum requirements of operating instructions include details on safe commissioning, use, mounting and dismantling, upkeep (main- tenance and fault clearance) and safe setting-up. It may also be necessary to specify special conditions for safe use (including information on improper use).

Equipment and systems may only be put on the market if they bear the CE mark and the manufacturer’s operating instructions and declaration of conformity are enclosed. The CE mark and written EU declaration of conformity confirm the product’s compliance with all requirements and assessment procedures stipulated in the EU directives.

Explosion protection in North America.

The basic principles of explosion protection are the same all over the world. Nevertheless techniques and systems have been developed in North America that differ considerably from the IEC system. The differences, for instance, can be noted in the classification of hazardous areas, equipment design and the installation of electrical systems.

INSTALLATION AND OPERATION

In the USA the National Electrical Code (NEC) and in Canada the Canadian Electrical Code (CEC) apply to electrical equip- ment used on hazardous industrial premises. These have the character of installation regulations for electrical facilities in all areas and refer to a number of further standards of other institutions which contain specifications for the construction and installation of suitable equipment.

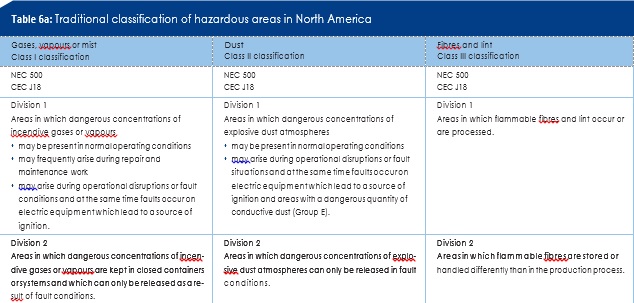

In North America, hazardous atmospheres are termed “hazard- ous (classified) locations”. Traditionally, hazardous areas are classified into “Class” and “Divisions” in North America. They comprise areas in which combustible gases, vapours or mists (Class I), dusts (Class II) or fibres or lint (Class III) may be pres- ent in dangerous quantities. Based on the likelihood or duration of the presence of these substances, the hazardous locations are traditionally subdivided into Division 1 and Division 2.

In 1996 the IEC classification system (zone classification) was also introduced for Class I. This amendment was implemented in Article 505 of the NEC, wherein users may choose the optimum system in terms of technology and economic efficiency. In 2005, Zones 20, 21 and 22 for areas with combustible dust (Article 506) were introduced.

The IEC zone concept for Class I was also introduced in Canada (CEC edition 1988), whereby all newly installed systems must be classified according to this concept. In the 2015 edition of the CED the zone concept was also adopted for dust explosion hazardous areas.

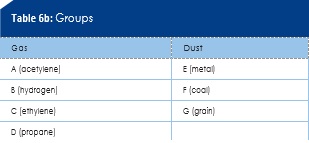

The traditional North American classification system divides Class I flammable gases, vapours, mists and liquids into gas groups (Groups) A, B, C and D and Class II combustible dusts into Groups E, F and G. The letter A denotes the most hazardous gas group, while in IEC and according to the new classification pursuant to Article 505, Group IIC is the most hazardous group.

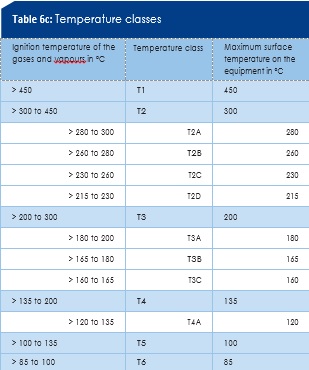

Determination of the maximum surface temperature to Article 505 in the NEC according to six temperature classes T1 to T6 is in harmony with IEC – with an additional subdivision into temper- ature classes in the division system. The existing temperature class system was not changed in the CEC 2015 either.

The installation method for the zone concept pursuant to NEC 505 complies as far as possible to the traditional class/division systems. Besides the use of fixed pipelines and mineral type MI in Class I, Division 1 or Zone 1, approved cables are also allowed. Special cables may also be used in hazardous areas in Canada.

Furthermore, various standards and regulations govern the construction and testing of explosion-protected electrical systems and equipment in North America. In the USA these are predominately the standards of the International Society for Measurement and Control (ISA), Underwriters Laboratories Inc. (UL) and the Factory Mutual Research Corporation (FM). In Canada the standards of the Canadian Standards Association (CSA) apply.

Enclosure protection types

The counterpart of IEC 60529, which determines the IP protec- tion types (Appendix 5.2) for enclosures, is the Standard Publi- cation No. 250 of NEMA (National Electrical Manufacturing Association) (Appendix 5.3) in the USA. These protection types cannot be exactly equated to those of the IEC as additional environmental influences (such as cooling liquids, cutting oils, corrosion, icing, hail) are addressed. It is to be noted that enclo- sure types 7, 8, 9 and 10 refer to enclosures for hazardous areas.

Certification

As a rule, electrical apparatus and equipment used on hazard- ous industrial premises are subject to approval in the USA and Canada. Exceptions include electrical equipment whose design, along with the nature of the explosive atmosphere in which it

is used, precludes ignition. The responsible authorities decide whether such equipment is subject to approval. Equipment which has been developed and manufactured for use in haz- ardous locations must be tested and approved in the USA and Canada by notified inspection authorities.

Original link: http://www.r-stahl.com