Equipment protection by special protection ‘s’

03/20/2018

The purpose of IEC 6 0079-33 special protection “s” for any equipment protection level (EPL) is to allow design, assessment and testing of equipment or parts of equipment that cannot be fully assessed within a recognized type of protection or combination of recognized types of protection because of functional or operational limitations and where the desired equipment protection level can be achieved by the use of this standard.

This standard is intended to provide a framework to demonstrate how essential safety requirements can be met if not covered by established standards, thus allowing for innovation and dealing with unknowns.

History

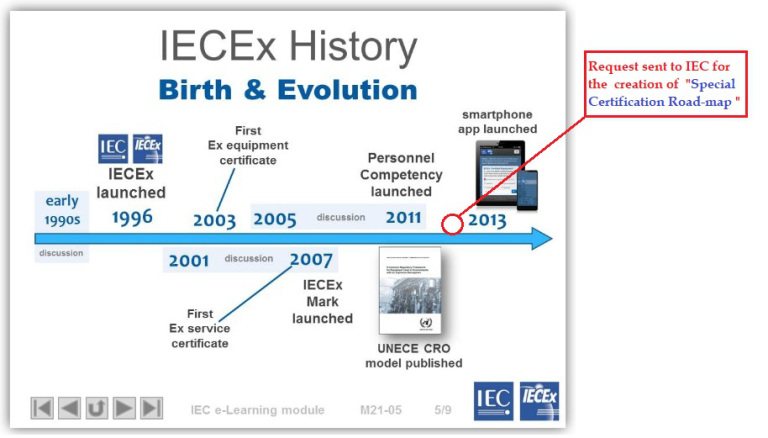

The creation of IEC 60079-33 is linked directly to the History of IEC Ex , when sometimes around or a bit before 2012, a request from the IECEx certification system was submitted to IEC to creat a road-map for certification (within the IECEx product certification Scheme) for such cases where the standards for existing types of protection were not applicable.

(Source IEC e-learning )

More interesting facts on History of IEC 60079-33 by Ron Sinclairhttp://www.hazardexonthenet.net/article/23777/How-Special-is-Special-Protection-.aspx

The need for a standard to address special protection “s” can be justified on the basis that:

• provision has been in IEC 60079-0 for many years with reference Ex “s” in a note in the

marking requirements or elsewhere. This reference goes back to IEC standards that predate

1957;

• there have been standards used on a national basis for many years for certification to

special protection “s”. Examples are SFA 3009 in the UK and AS/NZS 1826 in Australia

and New Zealand;

• it is necessary to have an international approach that is consistent;

• there is an identified need and has been a request for a special protection “s” standard

from IECEx.

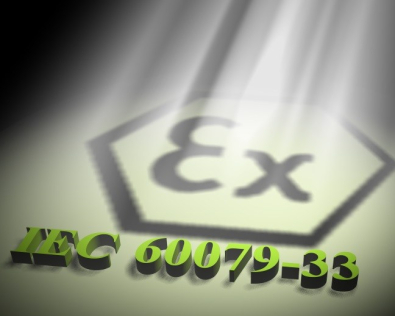

Let us bring IEC 60079-33 into the spotlight

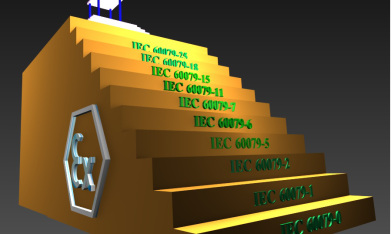

The scope of IEC 60079-33 lies beyond the present protection techniques as stated in IEC 60079 series

IEC 60079-33 is to be consulted only when all the existing options have been exhausted and the Ex Designers have to step into new a dimension , with a broad perspective.

Crossing-over and going beyond the safety steps of IEC 60079

..into the innovative land-of-options of IEC 60079-33

….and explore the protocol of this domain.

The most important part of the protocol is the INDEPENDENT VERIFIER

Independent verifier

A Person or organization, with the appropriate competency in the applied explosion protection methodology, responsible for the verification of design calculations, assessment and testing who are separate and distinct by management and other resources including financial, from the person or organizations responsible for all the activities associated with the design, manufacture or sales of the equipment. (IEC 60079-33 )

Of course, the need for the application of Special Safety “s” is initiated by the manufacturer along with the road-map/details of the process to verify the required level of safety .

The involved , level of Ex Competency of all the stakeholders ,clearly shows that IEC 60079-33 is only for the Ex-PERTS

IEC 60079-33 is quite sensitive about the role, and in turn the specifications of the Independent Varifiers .

Section 5 (IEC 60079-33 Edition 1, 2012) gives us the details about the :-

1. State of being Independent

This the most important aspect of an Independent Varifier so that the final endorsement procedure is not biased or tinted.

Independent verifiers shall be independent from the applicant and any organization that is involved in the design, manufacture or sale of the equipment. They shall be separate and distinct from those organizations by management and financial or other resources, so that any influence or pressure on the decision-making process, the assessment and the results can be excluded.(IEC 60079-33)

In section 6 ,there is reference to The Principles of Integrated Approach to Explosion Safety ,so let us remind ourselves, while designing an electrical equipment intended for use in explosive atmosphere, the application of the following golden principles :

(The 3 levels approach)

1. The electrical equipment should not release or produce explosive atmosphere at any level .

2. If explosive atmosphere do exists then ignition is to be prevented at all levels , taking into account, all the electrical-ignition sources.

3. The Aftermath of an explosion. An extensive analysis should be carried out so as to ensure the safety of persons & property at stake.

The road-map emerging from the application of these three principles will direct us to the EQUIPMENT PROTECTION LEVELS (EPL)