Do not underestimate danger of explosion; Even dust can destroy equipment and kill!

02/06/2018

The highest risk of explosion primarily threatens factories, where they work with dust in any way. Explosions occur directly in pieces of technological equipment during milling, drying, pneumatic or mechanical transport, storage and filtration, and they usually have fatal consequences. Unfortunately organic substance explosion do not only destroy the equipment, they also often kill.

Introduction

The year is 1987. Destructive explosion of flax dust in a linen factory in Harbin, China kills 47 people and injures another 179 (Los Angeles Times, 2015). On the second of August 2014 in early hours of the morning an explosion can be heard in a factory producing automobile parts in the Kchun-shan city in Eastern China (Fox News, 2015). The massive explosion kills almost 70 people and tens of others are injured. Explosion of whirled up aluminum dust is indicated as one of possible causes (The Guardian, 2015). The year 2015 is not an exception. World agencies informed that explosion of colored dust based on starch that was used at the festival Color Play Asia in June killed 10 people and injured another 485 (CNN, 2015), and that in August explosion in a warehouse of dangerous material in the Chinese port of Tianjin at least 44 people were killed and over 700 injured (CNN, Massive Blasts …, 2015). This information, that by far do not include every accident of this kind, shows one thing: Literary any dust can explode under ideal conditions, be it grain, flour, starch, sugar, dried milk, cocoa, coffee, coal or aluminum dust.

The highest risk of explosion primarily threatens in production processes, where dust is handled in any way. These processes are used, for example, in food, pharmaceutical or chemical industries. Technologies that companies use for milling, drying, pneumatic or mechanical transport, storage and filtration are highly susceptible to self-ignition, occurrence of fire and explosion. A series of accidents, fires and explosions, which happened in the past, turned attention of experts to development of systems and devices that could protect industrial technologies against these events (Fig. 1).

Methodology

Explosion can be in many cases prevented by active explosion protection, namely by exclusion of at least one of the three components needed for explosion of organic substances – initiation ignition source, concentration of explosive substance above lower explosion limit and oxidation agent. However, in about 40% of processing industry it is not possible to exclude even one of these initiation components, therefore quite safe conditions cannot be provided without passive explosion protection. Primarily technological processes during milling, drying, pneumatic or mechanical transport, storage and filtration are highly susceptible to self-ignition, occurrence of fire and explosion. In these cases the risk of explosion is high without the use of anti-explosion elements designed for a given technology on the basis of careful analysis by a professional company that works in the area of explosion prevention.

Design of explosion protection

When we consider equipment with potential explosion danger, we need to make sure that the equipment is suitably located, with regard to danger zones and layout of the construction project, already in the project phase of proposed technology. At the same time we need to make sure that the technology is resistant to all conditions occurring during explosion.

Not only operational conditions need to be expertly evaluated, but also each specific technological process and its equipment in such way that helps an operator or a project engineer to exactly determine a measure of explosion risk, and possibly propose a way to eliminate it or completely exclude the possibility of explosion. If experts, who are technically capable of determining that a substance is explosive, and who know its speed of explosion pressure increase, can actively participate in preparation of project documentation, then the best possible protection against explosion without technological limitations can be achieved. Unprofessional proposals of protective explosion elements in a technology can in many cases lead even to increase in explosion effects instead of their suppression. The result of complex explosive protection is a document called the Document on Protection Against Explosion that, based on fire technical and explosive parameters, specifies in detail environment classifications, types and numbers of safety elements, safety regulations for the technological process, defines possible ignition sources, safety zones, required measures in the area of electricity and electrostatic electricity, solutions for signalization and blocking and starting of operations after possible explosion. This document takes into account current state of technical equipment, as well as technological solutions in the area of machines and equipment.

Self-ignition risks

Possible causes of explosions of powder substances include self-ignition. At the same time reaching of critical temperature depends on substance properties, especially on kinetics of heat release, layer thickness, conditions of heat exchange with surroundings, and also on the length of time, for which the critical temperature conditions last. Fire or explosion can be caused also by mechanical impurities in insufficiently filtered air brought to technological equipment; friction areas of individual equipment parts are also risky (especially on various sprayers, fans and tourniquets), and danger is also represented by electrical sparks caused by static electricity or, for example, by friction of blades of dirty fan against its cover. These risks are present during processing of bulk materials in mills, crushers, exhaust equipment, during the process of drying or pneumatic transport of material, etc.

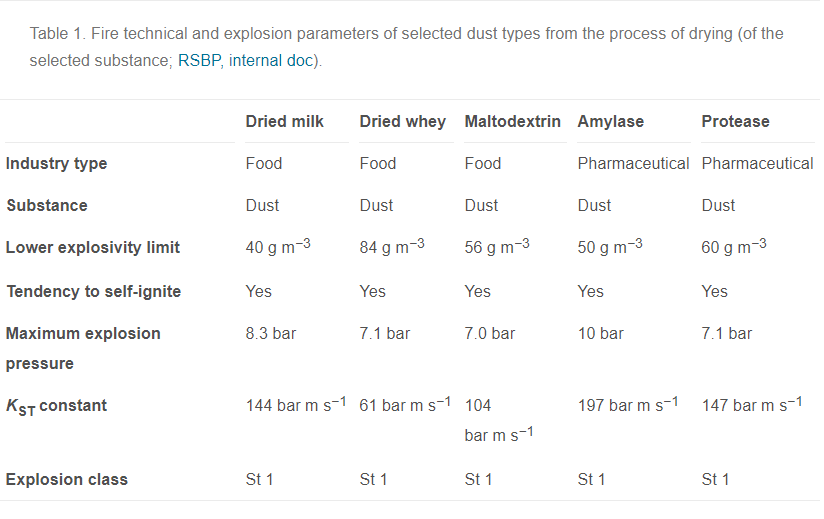

As an example I present fire technical and explosive parameters of selected types of dust during the process of drying. Table 1 shows common bulk materials that can be encountered in the food and pharmaceutical industries. Each substance has their lower and upper explosivity limits. They depend on dust grain sizes, their concentrations and spread in the environment and oxygen content and temperature of the environment. The finer and drier the dust is and the higher is the environment temperature, the more ignition-prone the substance is, and its explosion is stronger. Not only layers of deposited dust, that can be swirled up by different ways, especially in pipes, separation cyclones or filters, are dangerous, but also decreases in flow speed and increases in environment temperature, for example due to power outages, insufficient air filtration or imperfect cleaning of technological pieces of equipment.

Table 1 shows that dried milk, for example, that falls under the st1 explosive class, and that has tendency to self-ignite, has the lower explosive limit of 40 g m−3. There would be no explosion in case that its concentration falls under this limit. On the contrary, in case that it would get into contact with an ignition source, an explosion would certainly occur, and the maximum value of explosion pressure could reach 8.3 bar. It is similar with other substances; therefore they need special attention.

Passive explosion protection

Each model passive explosion prevention of industrial technological equipment includes installation of explosion relief or suppression elements. Both of these must be in combination with explosion separation. Before application of explosion protection elements we need to make sure that the equipment construction is resistant to explosion pressure. The extent of resistance against explosion pressure is specified in manufacturer or technology supplier documentation according to European or worldwide regulations and standards. If these values are missing, they need to be practically verified by static strength calculation of the selected parts of technology. Installation of explosion protection elements follows this verification of pressure resistance.

Complete explosion protection of industrial equipment includes three basic versions of explosion protection: (1) explosion suppression in combination with explosion separation; (2) explosion relief in combination with explosion separation; and (3) flameless explosion relief in combination with explosion separation. All explosion protection elements go through demanding development and a series of rigorous tests performed at accredited workplaces in order to ensure their optimization and hundred percent effectivity in operations and installed technologies.

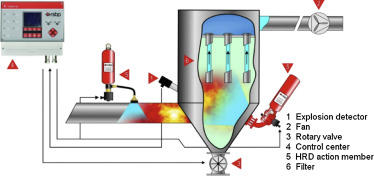

The explosion protection by suppression and separation of explosion (Fig. 2) is suitable primarily for equipment inside buildings, where it is not possible, for safety or other reasons, to relief the explosion to the environment or direct it, using anti-explosion pipeline, to a safety zone. In this case a HRD (high rate discharge) system is applied to the protected technology that detects the start of explosion inside the equipment and consequently performs quick extinguishing in the protected space. Explosion detectors react within 2 ms after set values are exceeded. A bottle with an extinguishing agent is equipped by a fast-opening valve developed for these purposes that releases the whole content of the bottle into the protected environment. This way it is possible to impact the explosion in its incipient stage already, and the HRD system thus effectively suppresses the explosion. It limits explosion pressure within the equipment under its pressure resistance, thanks to which destruction of the equipment is avoided. HRD barriers in pipes that can separate explosion from other related equipment parts are used to separate the explosion.

Figure 2. Explosion suppression in combination with explosion separation (RSBP, internal doc).

The version of explosion protection by explosion relief (Fig. 3) that is used to protect production equipment like silos for storage of bulk materials, exhaust systems, milling equipment with separators, drier complexes and pneumatic transport, is primarily suitable for equipment located in outside environment or for technological equipment inside buildings, where the flameless explosion relief can be used. In both cases under normal operating conditions the equipment relief opening is covered by an explosion relief panel. If an operational pressure is exceeded inside of the equipment, panels on its surface open and relieve pressure from the endangered area. The technology equipment is thus exposed to smaller pressure than is its pressure resistance, and therefore it will not be destroyed. Explosions can be relived to safe zones only.

Figure 3. Explosion relief on a testing vessel (RSBP, internal doc).

If the protected equipment is inside a technological building, the explosion protection with explosion relief is additionally equipped by a device for flameless explosion relief that ensures that the flame front does not get into the hall space. Temperatures up to 2600 °C can be reached during normal explosion relief. Thanks to a special construction of a device flame filter the temperature of the flame and combustion products can be lowered to the level that is not dangerous for technologies or personnel in the area. Such equipment does not need any operating personnel for its function (Fig. 4).

Figure 4. Flameless explosion relief on a testing vessel (RSBP, internal doc).

The separation of explosion or protection against its propagation to related equipment parts or production technologies can be solved, in these cases, for example, by installation of a back-flap that will be closed by a pressure wave in the case of explosion in the equipment (Fig. 5).

Figure 5. A back-flap installed on a pipe (RSBP, internal doc).

Conclusion

Industrial equipment explosions are not exceptional – on the contrary. As shown by the data in the introduction, explosions keep destroying properties and lives. The question of provision of maximum safety against explosions in industrial technologies or application of passive explosion protection thus becomes an important step in the global question in solution of protecting of personal and property safety. Operators should consult this area at least on the level of safety technicians. However, only professionals with long time experience, who completely handle safety of industrial operations and individual pieces of equipment from the point of view of fire and explosion protection, can create professional analyses on the subject and direct equipment operators to solutions of possible technical applications in such way that this protection (possible modifications of equipment) is safe not only for persons and workers in a particular operation but also for the equipment itself. We also must not forget the development of industrial equipment and its production. Currently manufacturers have whole lot of legislative tools at their disposal to lower or eliminate these dangers. Do not underestimate explosion danger – even dust can kill! The explosion protection and equipments described in the article comply with: CSN EN 1127 (n.d.), CSN EN 14 373 (n.d.), CSN EN 14 460 (n.d.), CSN EN 14 491 (n.d.), CSN EN 14 797 (n.d.), CSN EN 15 089 (n.d.), European Parliament and Council (n.d.), Stroch (2010) and Stroch (2007).

Conflict of interest

The author declares that there is no conflict of interest.

References

- Woodworking Network Woodworking Industry News, n.d.

- Combustible Dust the Source of Explosion at Chinese Auto Plant, Woodworking Network Woodworking Industry News (online). (quote 31.08.15] 27004534. Available from: http://www.woodworkingnetwork.com/wood-market-trends/woodworking-industry-news/production-woodworking-news/Combustible-Dust-the-Source-of-Explosion-a-Chinese-Auto-Plant-1.html.

- CSN EN 1127, n.d.

- CSN EN 1127-1: Explosive Atmospheres – Explosion Prevention and Protection – Part 1: Basic Concepts and Methodology.

- CSN EN 14 373, n.d.

- CSN EN 14 373: Explosion Suppression Systems.

- CSN EN 14 460, n.d.

- CSN EN 14 460: Explosion Resistant Equipment.

- CSN EN 14 491, n.d.

- CSN EN 14 491: Dust Explosion Venting Protective Systems.

- CSN EN 14 797, n.d.

- CSN EN 14 797: Explosion Venting Devices.

- CSN EN 15 089, n.d.

- CSN EN 15 089: Explosion Isolating Systems.

- CNN, n.d.

- More than 500 Injured in Explosion at Taiwan Water Park. CNN (online). (quote 31.08.15). Available from: http://edition.cnn.com/2015/06/27/asia/taiwan-water-park-explosion/

- The Guardian, n.d.

- China Factory Explosion Kills Scores, The Guardian (online). (quote 31.08.15). Available from: http://www.theguardian.com/world/2014/aug/02/china-factory-explosion-kills-scores-shanghai

- Fox News, n.d.

- Dust Explosion at Car Parts Factory in Eastern China Kills 69 People, Injures Nearly 200. Fox News (online). (cit. 31.08.15). Available from: http://www.foxnews.com/world/2014/08/03/dust-explosion-at-car-parts-factory-in-eastern-china-kills-6-people-injures/.

- European Parliament and Council, n.d.

- European Parliament and Council Guidelines 94/9/EC and 1999/92/ES.

- Internal RSBP, n.d.

- Internal RSBP spol. s r.o. documentation.

- Los Angeles Times, n.d.

- 47 Die, 179 Injured in Blast at Linen Mill in Northeast China. Los Angeles Times (online). (cit. 31.08.15). Available from: http://articles.latimes.com/1987-03-17/news/mn-12499_1_linen-mill.

- Massive Blasts Rock, n.d.

- Massive Blasts Rock Chinese City of Tianjin; 44 Dead, Hundreds Injured. CNN (online). (quote 31.08.15). Available from: http://edition.cnn.com/2015/08/12/asia/china-port-explosion/

- Stroch, 2010

-

P. StrochCombustion and Explosion Processes978-80-554-0187-4, EDIS publisher ZU, Zilina (2010)

- Stroch, 2007

-

P. StrochRisk of Dust Mixture Explosion and Prevention Possibilities(1st ed.), 978-807362-515-3, AMOS repro, spol. s r.o, Prague (2007)

Source: https://www.sciencedirect.com/science/article/pii/S2213020915000968