Can tea cause an explosion?

10/10/2017

Focus on safety

Lindor Gentle Touch Mixing, the Dutch manufacturer of industrial mixers, developed an industrial mixer for processing tea. One of Lindor’s European customers asked them to engineer and build the mixer to include an ATEX heater, zone 22, for their production plant in India. ATEX legislation is mandatory in Europe, but not in India. Reputable companies often have, as their company policy, the requirement to follow the same safety standards worldwide. As did this client. Safety first! Always!

Two industrial mixers under construction in the company hall of Lindor Gentle Touch Mixing, in Dordrecht, The Netherlands

So can tea cause an explosion?

Yes, it can! Dried tea leaves contain a certain amount of fannings or dust particles. This, when mixed with air in the form of a dust cloud, can cause an explosion if it comes into contact with a hot surface or a spark. The exact dust explosion properties of tea can be found in an online database. This database contains the dust explosion properties of more than 6000 dust samples.

Quality control: max. 80 degrees Celsius

In the process of drying tea leaves, hot air is blown into the mixer. If the airflow is too strong, the leaves will be blown out of the mixer. If the leaves become too hot, they burn and that will adversely affect the quality of the tea. Because the heater has a very low heat load, many meters of heating element are required. The 30 meters of heat element are tailor-made by a specialized company. A control panel, also a part of the ATEX-proof design, ensures the correct airflow and temperature.

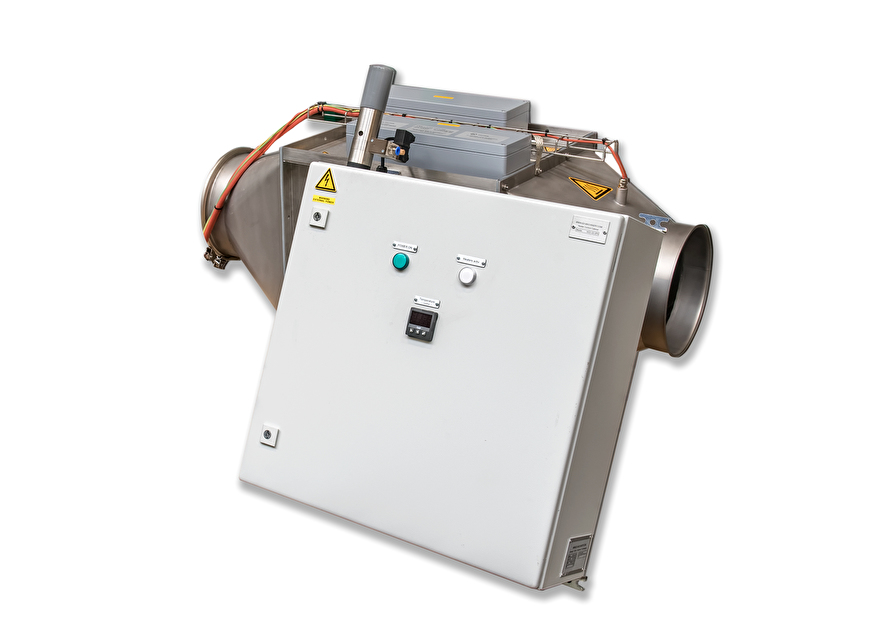

Ex-Machinery Special Solution. ATEX heater zone 22, for drying tea leaves.

Explosion-safe design: What makes this heater suitable for Zone 22?

1. Surface temperature

Ordinary process heaters quickly reach a surface temperature of 600 degrees Celsius. The fine tea dust particles have a MOT (minimum ignition temperature) of 510 degrees Celsius. The ATEX directive sets a calculation method to determine the maximum surface temperature of the device. Take the lowest result of the following calculations:

- Maximum ⅔ of the MOT (minimum ignition temperature)

- The ST (smoldering temperature) minus 75 degrees Celsius

In the case of our tea leaves:

MOT = 510 degrees Celsius → 510 * ⅔ = 340 degrees Celsius

ST = 300 degrees Celsius → 300 - 75 = 225 degrees Celsius

We have maximized the maximum surface temperature of the heater at 225 degrees Celsius

2. Non-sparking and impact-proof

To ensure safety, the ATEX heater should not spark. For dust-explosive zone 22, the equipment may not spark during normal operation. All interior parts of the heater and the control panel are tested and technically adjusted where necessary. In addition, the equipment needs to be impact-proof. The heater and control panel can take a knock. If, for example, a maintenance officer drops a tool on the equipment then there will be no harm done. Both the heater and control panel can withstand an impact of up to 7 joules of energy.

3. Protection against overheating in case of an error

In zone 22, you can take into account errors which may occur during normal use. One example is that if the fan fails, then the cooling of the heating element stops and overheating occurs. If this happens, the power supply is turned off "hard". This ensures that safety is guaranteed.

ATEX control panel for operating the ATEX heater.

Did you encounter challenges while making the ATEX heater?

“Practice always proves to be more intractable than theory”, says Gido van Tienhoven, ATEX specialist of Ex-Machinery. “With regards to the uniform heating of the airflow, we faced an issue. In the "in operation" test, the air vortex pattern proved to be a problem. Some elements became too hot. An infrared camera showed us exactly which parts became too hot, so we measured those parts piece-by-piece – at the lowest and at the highest position of the heater. The airflow in the heater has been modified accordingly and can now safely dry tea leaves.”

About Ex-Machinery

Ex-Machinery has specialized in ATEX and explosion safety for over 14 years. Are you interested in explosion-proof equipment? Then please do follow our ATEX specialist Gido van Tienhoven on LinkedIn and he will keep you updated on ATEX and explosion safety. You can also send Gido your specific ATEX question. We are committed to working with you to help you find your ATEX solution.

Source: http://www.ex-machinery.com/a-49304309/blog/atex-heater-special-solution-for-the-food-industry/